SEARS KENMORE 68 95 96 1600 1650 1651 1652 1654 1700 1750 1751 1752 SEWING MACHINES

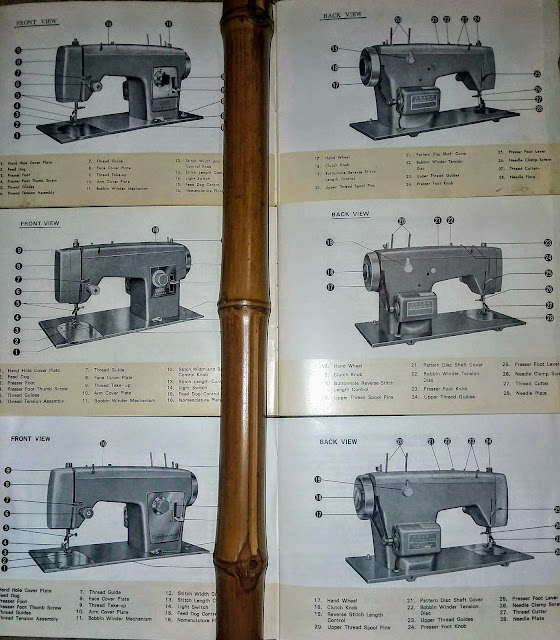

Sears Kenmore Model 95, 1652, 1750 illustrations from the manuals

Top to bottom 95, 1652, 1750 manual comparison of machines

Top to bottom 95, 1652, 1750 manual comparison of machines

TIP- most of these models require the C cam #1 to ZIGZAG

1750 under the lid- Notice the simplicity of the mechanisms, one of my favorite aspects of these models.

1750 front view buttonholer in front of it is missing some cams

| ||

Top to bottom 95, 1652, 1750 manual comparison of machines

|

TIP- most of these models require the C cam #1 to ZIGZAG

|

| 1750 under the lid- Notice the simplicity of the mechanisms, one of my favorite aspects of these models. |

|

| 1750 front view buttonholer in front of it is missing some cams |

|

| Diagram copyright owned by Searspartsdirect dot com Kenmore 158.950 feed diagram |

Zigzag stitch width IS WIDER in the luxury models, and is the big difference between some models, as well as some have chainstitch capability, while others do not. The number of cams varied by model number, as did other accessories.

|

| Stitchsamples on left came with brand new machine from the factory, proving the stitches it could sew. Others were my home sewn stitch samples on scrap fabrics. |

Sears website parts research area, shows the drawings of the various accessory sets, with the machine model numbers they went to. Often, the only difference in the model number, literally was the accessories & feet that the machine came with.

|

| Style C Kenmore cam stitch designs all 45 |

CAM STITCHES AND STRETCH STITCHES NOT STITCHING CORRECTLY-

If your stretch stitches, or decorative cam stitches are not stitching properly, even when you have the machine set correctly, your stitch regulator may be frozen with dried oil. It is a quick and easy fix, I have given more in depth details for Kenmore models, including videos, in this blog post -

https://tumorfarmer.blogspot.com/2019/11/kenmore-reverse-stitch-regulator.html

Circular stitcher, allows you to stitch perfect circles, of various sizes, by attaching this metal attachment to the machine bed. It fits all Sears Kenmore vintage machines, because the screw for attaching the seam guide, is the same distance from the needle, on all Kenmore machines made by their manufacturers.

Another oddity regarding Sears Kenmore Sewing Machines- while all of the repair people I have checked with have said that the model number of Sears Kenmore sewing machines is the first 2 to 4 numbers to the right of the decimals on the nomenclature plates, many of the manuals have another set of numbers entirely. There seems to be a very long period of time where the Kenmore sewing machine models did not seem to change much- they didn't need to, they did everything that any other sewing machine did, and because the only real differences between the different "models" were based on which set of attachments & accessories were sold with them. The more you paid, the more stitch cams, attachments & accessories you got with your machine. Model 1650 seems like it should be very different from model 95, but as you can see from their manuals, they are the same machine, with only a few tiny decorative differences, according to their manuals!

I used to prefer the Sears Kenmore models with built in cams, simply because they didn't require cams to sew special stitch designs. Now I prefer models which have some built in cams, but also accept more cams, because it means I can sew up to 45 different stitches with those machines, since I have purchased all of the Sears cams for the main 158 models, which some of us refer to as type "C" cams. There are several models with 7, 10, 12, or other numbers of utility & some decorative stitches, usually they say "Ultra" before the number of stitches. They usually have the dual belt system, with the motor inside the bottom of the machine, rather than off the back.

Yes, I forgot to answer the earlier question about how to get the machine off the zig zag stitch! Oops! Tabor8man, to change it from a zig zag stitch to a straight stitch, you can either turn the stitch width down to 0, and/or you can remove the cam under the door on top of the machine. It will only do a zig zag stitch if it has a zig zag cam in the machine, and has the stitch width turned up above 0.

The greatest advantage of these Japanese made heavy metal sewing machine treasures, is that they are extremely simple, mechanically! The ONLY reason you see posts from Bernina & other brand sewing machine repair technicians that claim the old metal Kenmores are only good for using as an anchor, is because the Kenmores almost NEVER break down, & if they do, you can easily fix them yourself if you can find the parts!

That means that the technicians for the most expensive brand name sewing machines are not getting paid any money to fix or maintain your sewing machine, because it is so easy, you can do it yourself! The only all metal old Kenmore sewing machines that would be considered only good for boat anchors, were the ones made by New Process Gear, a division of Chrysler, in the U.S.A.. You can easily identify them by their manufacturer code on the metal nomenclature tag on the machine. 120 are the first 3 numbers before the decimal point. You can easily identify them, not only by the numbers, but you can see Chrysler design in their ugly shapes, they look like they are supposed to be an old automobile accessory, not a sewing machine. I have seen one of those early Sears Kenmore sewing machines completely repainted, with gorgeous red automotive paint, & WOW!!! Apparently it is a powerhouse machine, at least according to the person who totally repainted their New Process Gear Sears Kenmore sewing machine, so if you find one that works well, or just needs cleaned & oiled, maybe new wiring, give it a try!

Freearm Kenmore portable machines do have 2 weaknesses to be aware of, but they do not affect sewing & stitching ability, at all. In order to make the freearm bobbin cover to snap shut again, a steel spring was built into the bottom of the freearm. It presses against the plastic bottom cover of the freearm, & over time, the plastic becomes brittle, & weakens, until the stronger steel is able to force the plastic to chip off, in the area where the hinge spring presses against it. To make the door stay closed, once this has happened, your best bet is to use a piece of tape, to hold the bobbin door closed. I usually fold the end of the tape over on itself, to make a fingerhold, so it is easy to open & reclose the bobbin door. Even if you super glue the broken off chip of plastic, back where it broke off, it will not stay in place with repeated opening & closing of the door. It is possible to simply remove the bobbin cover, instead, but that is up to the individual machine owner.

The second weakness is the bobbin winders on some models have air bubbles in the pot metal used to mold these metal parts. The air bubbles weaken this area, & over years of temperature changes, & air pressure changes, these can literally crack on their own, and when someone touches it, it will break in 2 or 3 pieces. It does not require any force for it to break, when it gets to this point, so please don't blame it on someone you loan the machine to, or a technician who is oiling the machine. Pot metal is not high quality metal, it is one reason the old black Singer machines are so highly valued, they had much higher quality metal inside & out. People are rediscovering those incredible machines, for their strengths, too.

The only reason many perfectly good sewing machines are sold for as low as $10, is because of the super cheap clothing available due to the unfair trade status caused by the Free Trade agreements made by foolish and/or dishonest, greedy politicians who literally gave away American jobs, by making laws that made it easier for wealthy American business owners to shut down their American factories, & re open them in Mexico, China, India, & other countries with super low wages, no worker protection laws, so the laborers can be abused, forced to work inhumane hours, & in dangerous labor conditions, and there are no laws in place to protect consumers from unsafe chemicals or other dangers in items made in countries with no consumer safety laws.

If Americans & other wealthier countries still had to sew their own clothing, or pay others to make their clothing, the prices of these high quality used sewing machines would be at least $500, & if they have more special stitches & accessories, they would be around $1,500.

While I wouldn't mind if someone gave me a new computerized sewing machine, and I would definitely try it out, I suspect that I would still prefer these great metal, mechanical Sears Kenmore Sewing Machines for most of my sewing!

While I do love many of the European sewing machines made around the same time as these old Kenmores, the European sewing machines are much more complicated mechanically, making them more likely to need repairs done by a factory certified technician for the brand of the specific sewing machine. I do love the mechanical Bernina's with their special presser feet, tiny darning & embroidery hoop, accessory case, free arm & extension table, extremely informative manuals, & wonderful carry cases, as well as the Elna Supermatics with 100 or so different stitch cams available, well designed presser feet, accessory cases & incredible metal sewing case which fits around the freearm, making a large sewing table!

OK, if you can't tell, I LOVE any good sewing machines, & the easier they are to sew with & maintain, the better I love them! Having well written sewing machine manuals with lots of photos, a broad range of stitches, accessories & attachments, as well as a well designed carry case, really does impact my decision when choosing which one to be my "one & only" sewing machine! I have more than 22 right now, so you can see I'm not doing very well in the choosing department! LOL!

Becky in NC tumorfarmer

A wonderful individual, David Goboff, created a Kenmore sewing machine Model Chart which helps tell what each model can do, and what accessories originally came with them. Here is a link to his chart.